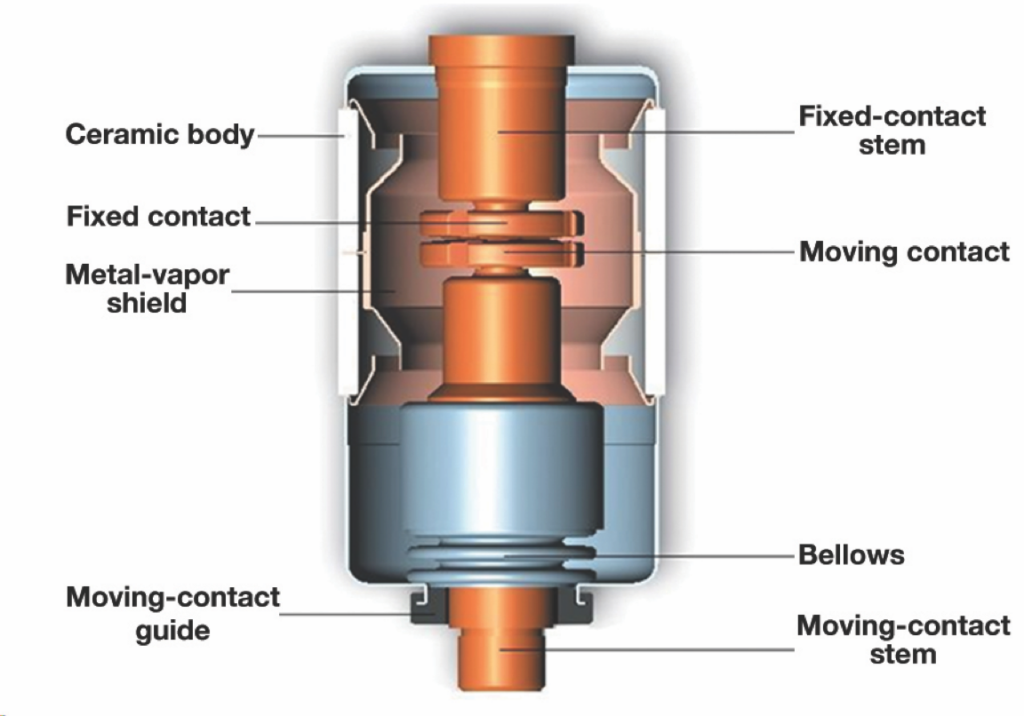

As their name implies, vacuum interrupters stop the flow of AC power between a pair of electrical contacts using the high vacuum within which they are enclosed. These hermetically sealed devices are typically designed for use with applied voltages from 2 to 38 kV. A vacuum interrupter can stop tens of thousands of amps when the contacts are open, essentially acting as an insulator that can withstand full system voltages.

The units are typically applied as circuit breakers, which interrupt current only in the rare event that it exceeds a nominal value, and as contactors, designed to open and close frequently to operate machinery, such as conveyor belts and rock crushers. Of the two contacts within the vacuum interrupter, one is fixed and one moves via a bellows mechanism. The bellows draws the moving contact away from the fixed one when it’s necessary to interrupt the current.

Most vacuum interrupters have a shelf life of about 20 years. But many units installed in the 1970s and 1980s are still in service today. Thus they have far exceeded their life expectancy. A vacuum interrupter failure could result in unnecessary downtime and equipment damage. For that reason, vacuum interrupter testing is a critical part of proper maintenance.

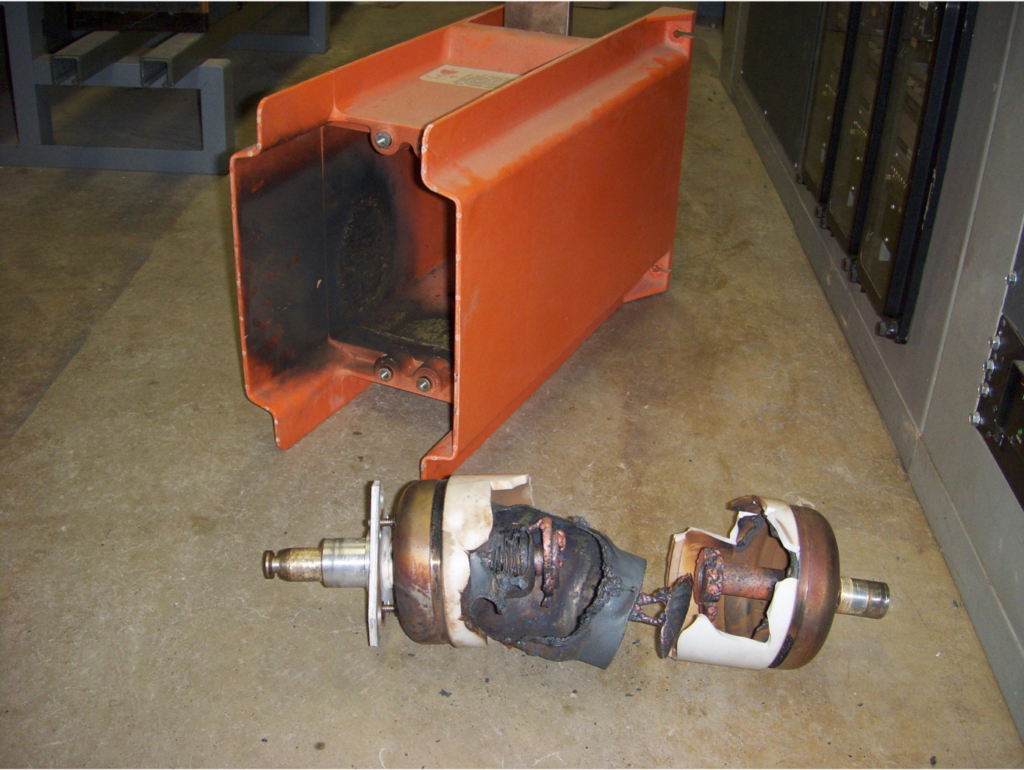

What Failure Looks Like

Failure in a vacuum interrupter can take a few forms. One failure mode is contact erosion. Because an electrical arc forms as the contacts are separated under load, the arc vaporizes some of the contact material every time the unit is opened. Over time, enough material will be removed to affect the unit’s performance.

Mechanical failures can also occur. These include failures of brazed joints or critical components, such as the bellows, which is very fragile at only 1/5000 to 1/7000 of an inch thick. The interrupter can also lose vacuum, which means the unit will no longer be capable of insulating the high voltage.

Testing Vacuum Interrupters

The traditional approach to testing vacuum interrupters is the high-pot test. However, this is simply a pass/fail test — either the unit works or it doesn’t. The high-pot test cannot reveal the remaining life expectancy of the interrupter or identify potential issues.

One test for determining the impact of contact erosion is measuring contact resistance. This will reveal how good the connection is between the two contacts and if there is any serious pitting on either surface. Measuring the change in the length of the vacuum interrupter over time is another test that will identify the extent of any contact erosion.

Determining the status of the vacuum within the interrupter is one of the best ways to know if and when it might fail. Manufacturers of vacuum interrupters test the units at the factory using a Penning discharge test. With the contacts open, a high DC voltage is applied, which results in a small leakage current. When a strong magnetic field is also applied, the leakage current becomes trapped, creating additional current inside the vacuum interrupter that’s proportional to the number of gas molecules inside. The fewer the gas molecules — and thus the better the vacuum — the lower the current will be.

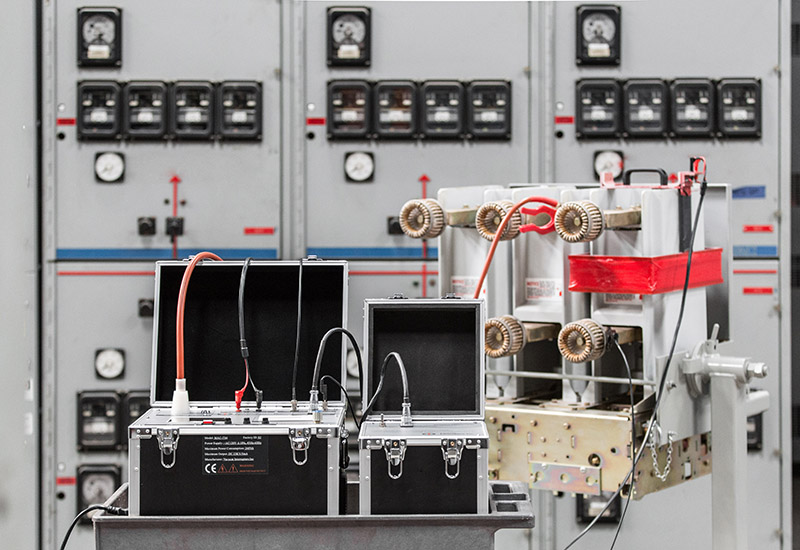

Advantages of Vacuum Testing With the MAC-TS4

The MAC-TS4 vacuum interrupter tester is a first-of-its-kind portable magnetron atmospheric condition test system. It allows the Penning discharge test to be conducted on the shop floor or in the field. Because of patented magnetic field coils, the vacuum interrupter can be tested in place — inside a circuit breaker or contactor. By testing the vacuum level over time, it’s possible to extrapolate when the vacuum inside the unit will no longer be able to interrupt the power flow and will fail.

The MAC-TS4 is completely self-contained. It incorporates a high-voltage power supply, backlit LCD display, built-in thermal printer, and complete set of test leads. A USB connection allows the technician to operate the test kit with an external PC as well as download stored test results and generate reports.

The rigid magnetic field test coil allows technicians to test vacuum interrupters that are inaccessible. The MAC-TS4 can also be used to test vacuum interrupters that have been removed from a circuit breaker or contactor. The technician can use a magnetic field coil test fixture in conjunction with the test set. The fixtures come in a variety of sizes to accommodate most vacuum interrupters.

If you have vacuum interrupters that may have exceeded their life expectancy or could soon fail, contact Vacuum Interrupters to learn more about testing and replacing your devices.